Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Manganese Ore Beneficiation Production Line

Manganese Ore Beneficiation Production Line

Manganese ore production line is not a single or a few equipment, but a whole set of manganese ore dressing equipment combination forming a production line, Which is suitable for large and medium manganese ore concentration plants and has good effect for beneficiation of manganese oxide and manganese carbonate.

The gravity separation is the main beneficiation method for manganese ore separation, followed by magnetic separation and flotation method. Gravity separation method is suitable for most of the manganese oxide and manganese carbonate ore dressing. Strong magnetic separation method is just used as an aid in the process of gravity separation process for recovery of fine grained manganese mineral with high oxidized degree. Flotation process is used only for part of carbonate manganese ore separation purification. By contrast, magnetic separation and flotation take relatively small market share. Here, Forui introduce gravity beneficiation production line for manganese ore to you.

Manganese ore gravity separation line generally includes crusher, vibrating screen, jig machine, dewatering screen and sometimes or washing machines and other equipment. Undressed ore must be broken, control the manganese ore granularity within the best feeding size, so crushing machine is necessary in manganese ore dressing production line.

For low silt content manganese ore, it can be feed the gravity separation directly after crushing and screening, but for large silt content and strong viscosity manganese ore, washing operation is needed after crushing to wash away too much sticky soil. The broken ore also need access to the screen flow for screening classification, because gravity separation equipment has very strict requirement on the size of manganese ore, if the material particle size is not in the working scope of gravity separation equipment, it often cause bad beneficiation indexes. So the screen flow is also the indispensable process in manganese ore dressing production line.

After crushing, screening and washing, manganese ore enters the corresponding storage bin. There also need to set a automatic feeding equipment to ensure the manganese ore can be evenly feed into the gravity separation equipment and get the best separation effect.

After jigging machine separation, the manganese ore concentrate and tailings are discharged accompanied by a lot of water. Before being transported to the concentrate or tailing factory, they must go through dehydration process. So setting a dewatering screen after the jig machine is also very important.

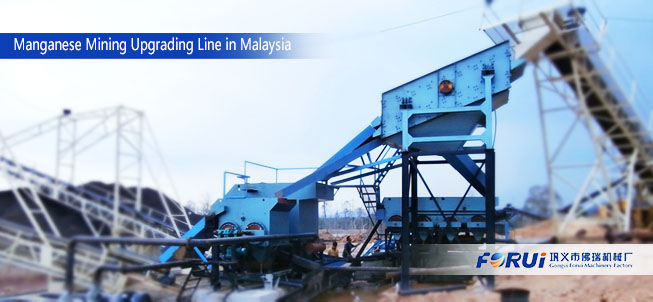

The picture below shows the manganese ore beneficiation production line in Malaysia.

For decades, gravity separation method has always been the mainstream for manganese ore dressing, and the equipment configuration can be crusher, washing machine, vibrating screen, jig machine, dewatering screen, etc. In order to ensure the rationality of the manganese ore dressing production line as well as high efficiency, Forui machinery carry out small test platform and free manganese ore dressing test can be done for the customer, we offer customers the reasonable design of ore dressing process flow and equipment configuration.