Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Tin Extraciton

For further concentration, jigging machine can be chosen as tin processing machine. A combination processing of screening-ore washing-jigging is needed to get high grade tin concentrate.

Alluvial tin processing is similar to that of alluvial gold extraction, and usually screening, ore washing, and gravity separation are involved. I.e. gravity separation is the only rough separation method for alluvial tin and alluvial gold mine. That is because tin and gold content is low comparing with other minerals, and kind of high-efficient and energy-saving extraction method and equipment shall be needed to enrich tin and gold from the alluvial mines. And here gravity separation is, obviously, kind of an ideal beneficiation method to get high grade tin and gold concentrate. Here is some information about alluvial tin extraction and tin processing machine from Forui.

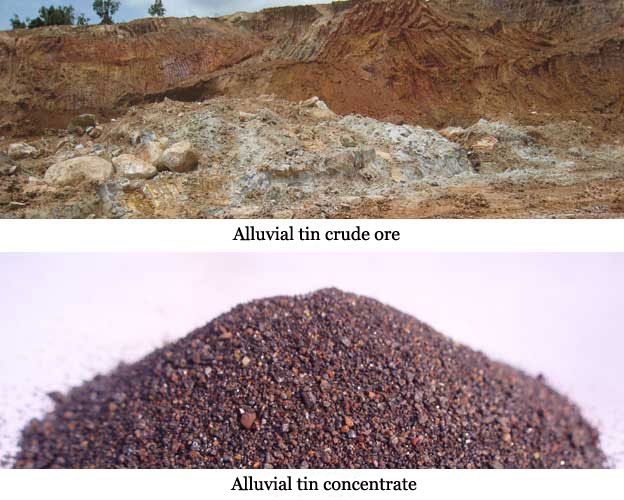

The following picture is about the test of alluvial tin ore by jigging. The upper part is about the raw tin ore while the down part is about tin extraction from tin processing machine-Jigging machine.

A great enrichment efficiency can be seen from the picture. Actually, a complex processing of screening-ore washing-jigging is needed to get high grade tin concentrate in the picture.

1. Alluvial tin ore washing plant

There are many stones or gravels without any tin element in the raw alluvial tin ore, and this will lower the following gravity separation. So the first step is to remove the stone blocks from the raw ore to improve the handling capacity and guarantee the enrichment efficiency. The common screen for alluvial tin ore is rotary screen like the picture above shows.

2. Alluvial tin ore washing equipment

For alluvial tin ore with a lot of sticky clay, ore washing will be needed to break the clay blocks besides screening. This will lower the possibility of tin coated by clay and improve the recovery rate and concentrating efficiency as well. The ore washing machine for alluvial tin processing is usually rotary ore washing machine, ore log washer.

There are still a lot of impurities after screening and washing and gravity separation will be needed as further enrichment. And here the gravity separators are required of large handling capacity and high recovery rate. The low efficient gravity separator of small capacity like shaking table and spiral chute will be out of consideration here.

Jig concentrator is usually adopted as gravity separator and can be chosen as tin processing machine. The main jig concentrator for tin processing is trapezoidal jig concentrator and down-driven jig concentrator. Generally, high grade tin concentrate can be gained after jigging gravity separation for alluvial tin of high single separation degree. For alluvial ore of low single separation degree, further milling will be needed to gain ideal beneficiation efficiency. Here gravity separation as rough separation not only lower the floatation cost and the plant investment, but also gain final concentrate for tin ore of high single separation degree. Therefore, as a tin processing machine, gravity separation and gravity processing machine is essential to alluvial tin processing. The following pictures are about the tin processing site of alluvial tin ore in Indonesia.

Here as a professional manufactures of tin processing machine, Gongyi Forui Machinery can do free tin processing test with our tin processing machine if samples can be available. And flow sheet and plant allocation can be designed according to the test result.

Related Video