Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Floatation Separation Plant

Floatation extraction is kind of beneficiation method on basic of mineral physical and chemical difference. Free test can be done with our flotation extraction plant if samples can be available.

Application of Flotation Extraction:

Application of Flotation Extraction:

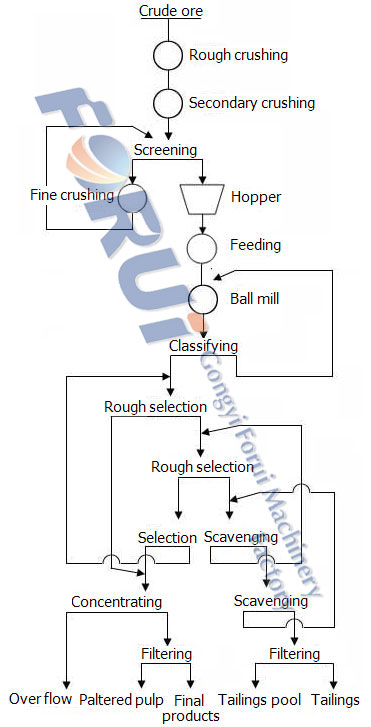

Floatation extraction is involved to beneficiate gold, copper, graphite, sulfur, talc, molybdenite, nickel, lead, zinc, and some other fine inlay ore. This is a general flow sheet of floatation extraction and further details will be needed for an exact flow sheet.

Introduction to Flotation Extraction Plant:

Introduction to Flotation Extraction Plant:

Floatation extraction is kind of mineral beneficiation method on basic of mineral physical and chemical difference. Surface of mineral granules can be of hydrophobicity, olepphylic,or hydrophobicity can be activated by a certain chemical. After a processing line, the mineral granules can be combined with the bubbles and floated to the surface of the pulp, and the concentrate will be collected from bubbles.

Before floatation extraction, the mineral granules shall be made liberated from the gangue, so crushing and milling will be needed to make the mineral size ok for floatation separation. Chemicals needed will be added to the milled pulp and agitator will be used to mix the pulp evenly and make the chemical and mineral granules engaged fully. And this will make the floatability difference bigger. The agitated pulp will be put into the floatation slots stirred and air inflated. Mineral granules with good floatability will attach to the bubble and go up to the pulp surface as mineralized foaming, and it will be overflowed or mechanically scraped to the concentrate slot. Concentrate can be gained after dewatering and drying. Sometimes the useful mineral will be left in the pulp while the unuseful materials with good floatability flow as output, and this is called reverse floatation. Eg.: floating the quartz from iron ore.

During the floatation separation, crushers, ball mill, classifier, agitator, floatation separation machine and assistant device will be involved to finish the whole floatation process.

Chemicals Involved:

Chemicals Involved:

Collecting agent, foaming agent, regulators can be involved during floatation separation. However, different chemicals as collecting agent, foaming agent, regulators will be needed for different ores.

You are welcome to Forui Machinery. Free test can be done with our flotation extraction plant if samples can be available. Our telephone +86-371-64391589 can be available for 24 hours or contact us via Email: info@frjigmachine.com