Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Mineral Processing Machine

Forui provides professional mineral processing machine with high quality. Mineral processing involves comminution; sizing; concentration and dewatering. We do free beneficiation test for you with our mineral processing equipments.

Forui Mineral Processing Machine

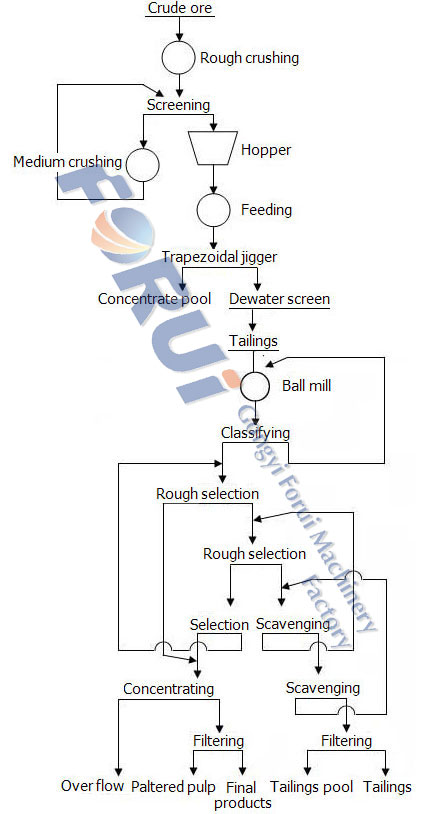

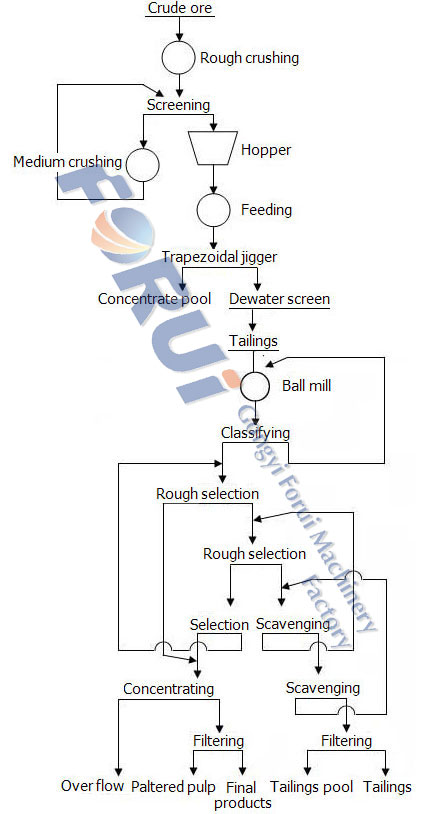

In the field of mineral extraction, mineral processing, also known as ore dressing, is the process of separating valuable minerals from their ores. Mineral processing can involve four types operation: comminution–reduction of particle size; sizing–separation of particle sizes by screening or classification; concentration-taking advantage of physical and surface chemical properties; and dewatering–separation of solid and liquid.

Comminution

Comminution

Both dry materials and slurries can be carried out by comminution. Crushing and grinding machine are the two primary comminution machine. Grinding is normally carried out after crushing. Forui jaw crusher is used for crushing the materials whose compression strength is not more than 320 MPa and Forui rod mill can be used in first level open-circuit grinding, widely applied to artificial stone/sand, mineral processing plant, chemical plant and power plant. Forui fine crusher is especially suitable for fine crushing hard and brittle materials and crushing abrasives, refractory, cement, quartz sand, steel emery and so on. This mineral grinding machine can be also used for crushing smelting slag such as silicon manganese, ferrochrome, nickel iron, copper, etc.

Sizing

Sizing

Sizing refers to separation of particles according to their size. The most commonly used sizing process is screening, and the screening equipment in Forui include vibrating screen, rotary screen and spiral classifier. Forui spiral classifier can be used for grading sand and fine mud in the gravity separation, classifying mineral size in metal ore washing, mud removal and dehydration.

Concentration

Concentration

There are many ways to increase the concentration of the wanted minerals. Forui suggest that the method chosen should depend on the relative physical and surface chemical properties of the mineral and the gangue. Gravity separation is a main mineral processing method used for mineral concentration. Jigging concentration plays an very important role in mineral concentration. Forui jig concentrators have good performance on the concentration of a large number of minerals.

Magnetic separation

Magnetic separation

Magnetic separation is a mineral process in which magnetically susceptible material is separated from a mixture under the magnetic force. This separation technique can be useful in mining iron as it is attracted to a magnet. Forui provides mineral processing machine-magnetic separators with wide range and high quality. Permanent magnet drum magnetic separator is mainly used for the magnetic roughing and featured separation. The magnetic system of permanent magnet drum magnetic separator consists of the strontium ferrite magnets.

Dewatering

Dewatering

Dewatering screen is an important equipment in mineral processing. The purpose of dewatering is to remove water contained in particles. Forui dewatering screen is a good mineral processing machine that has wide application in the mineral processing of coarse and medium grained minerals separation and dewatering of barite, fluorite, hematite, limonite, mirrors, iron ore and manganese ore etc.

Forui also provides mineral processing equiptments that can deal with a wide range minerals like iron ore, manganese ore, gold ore, tin ore, etc. You can't miss the the right mineral processing machines in Forui.