Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Mercury Ore Dressing Gravity Separation Line

Gravity separation method is suitable for processing of the mottled mercury ore and coarse grained disseminated mercury stone ore. Flotation process is mainly used for extraction of disseminated mercury stone.

Mercury ore is mainly composed of mercury and cinnabar. Cinnabar is red mercury sulfide content and the specific gravity is 8.1-8.2 with good natural flotability. The beneficiation methods can be flotation and gravity separation method, sometimes also USES gravity-flotation separation process.

The structure of Mercury ore is complicated with disseminated, mottled or block state. For block disseminated mercury concentration, the single gravity separation method can obtain ideal mineral processing index. For the concentration of disseminated Mercury ore, flotation method can be used. For punctate low grade mercury processing, gravity separation-flotation combined process may be used for dressing. Here let's take a look at the picture of mercury ore:

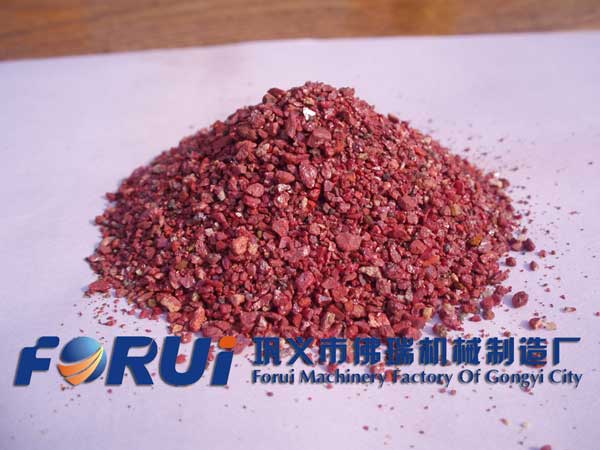

From the picture, we can see 3 different mercury stone, among which the separation of block mercury stone and mottled mercury ore dressing is relatively simple. However the disseminated mercury ore is not that easy because of the mutually disseminated between mercury content and waste rock. Breaking the conjuncture is needed to extract mercury content. The grain size of mercury ore after grinding is very fine, gravity separation method has been unable to deal with it. Even though the flotation method is with equipment investment, the added value is high, flotation of lower grade mercury ore still have higher economic returns. Sometimes in order to reduce the production cost and improve the beneficiation indexes, it also adopt gravity separation-flotation process of the mottled mercury ore separation. By gravity separation, large amount of waste rocks are abandononed, which can reduce the cost of subsequent grinding and flotation and equipment investment and increase the rate of the effective work of the follow-up process. Then flotation process is used to purify the coarse concentrates after gravity separation to get the final product. This combination process is most suited to the beneficiation of mottled mercury ore. The picture below shows the mercury concentrates processed by Forui jigging machine:

Gravity separation method is suitable for processing of the mottled mercury ore and coarse grained disseminated mercury stone ore with the advantages of high efficiency, small equipment investment, low operation cost and pollution-free for the environment, and the disadvantage is that the fine grained disseminated mercury stone recovery rate is low. Flotation process is mainly used for extraction of disseminated mercury stone. Due to the high flotability of sulfide mercury stone, flotation can be a right method for achieving good mineral processing index, but the equipment investment is big with high operating costs. It also has the certain pollution to the environment.

♦ Gravity separation process: broken - screening - jigging - shaking table.

♦ Flotation process: crushing - screening - grinding - classification - mixing floatation - filter.

♦ Gravity - flotation combination process: Crushing - screening - gravity separation - dehydration - grinding - classification - mixing - flotation - filter.

Gongyi Forui Machinery is a professional mining machinery manufacturer based in China. We has rich experince in mercury ore dressing and equipment. Small mercury ore dressing test can be carried out to customers for free. Welcome to contact us for more information. Email: sales1@frjig.com