Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Research on Mercury Ore Beneficiation Process in Indonesia

Customers from Indonesia visited Forui Machinery on 30 November 2013 and made discussion and comunication on the mercury ore beneficiation technology. They speak highly of Forui mercury ore processing technology and equipment and established initial cooperative relation with Forui Machinery. Now let's take a look at the mercury ore beneficiation process for the Indonesia customers.

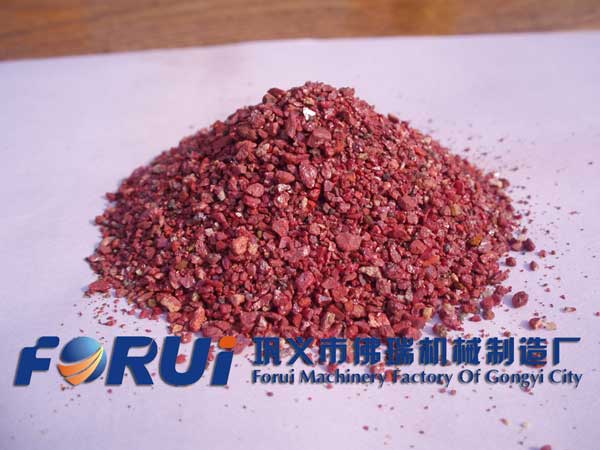

The following picture shows the mercury ore brought by Indonesian customers, from which we can see the mercury ore is of uneven thickness disseminated structure and there is apparent boundary between mercury and gangue minerals. The gangue mineral are mainly carbonate gangue and quartz, so there is significant specific gravity difference between mercury sulfide and gangue minerals. For this type of mercury ores, Forui adopts combination method of gravity separation and flotation.

Firstly, use gravity separation to pre-select the coarse mineral particles of mercury with high quality. However the fine mercury particles might be lost during the crushing or process, it is necessary to recover the tailings after gravity separation by flotation method for the purpose of improving the whole recovery rate. The combination method of gravity and floatation is proved not only increase efficiency and reduce processing costs, but also improving the mercury ore beneficiation indicators, is the best beneficiation method of coarse disseminated mercury ore beneficiation currently. The following picture shows the mercury ore concentrates produced by the combination method.