Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Mercury Ore Beneficiation Process

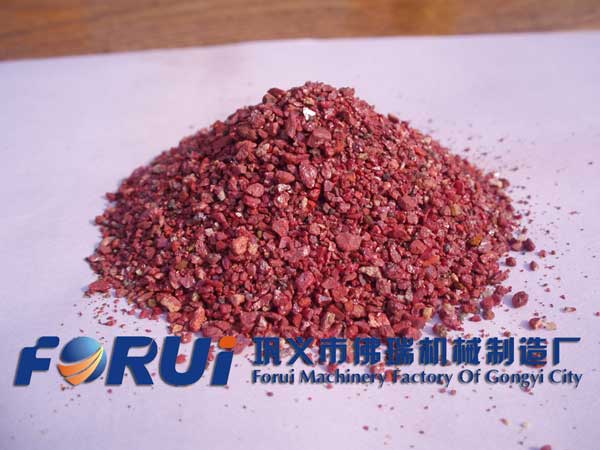

The products from mercury ore are mainly mercury and cinnabar. Liquid mercury ore dressing is relatively simple. Here we mainly introduce cinnabar(vermilion) purification methods and processes. Cinnabar is red mercury sulfide minerals, specific gravity 8.1-8.2, good natural floatability. Flotation and gravity separation are commonly used beneficiation methods, sometimes use the combination method of gravity separation and flotation.

Depending on the types of mercury ore, its beneficiation methods and processes are different. can be gravity separation, flotation or gravity-flotation separation.

Mercury ore structure is relatively complex, there are disseminated, blotchy and massive structure. For massive mercury ore processing, the gravity separation or hand selection can handle it; for disseminated mercury ore beneficiation, flotation method would be a good choice; for patchy low grade mercury ore beneficiation, combination of gravity separation and flotation is usually adopted.

Sometimes in order to reduce production costs, improve mineral beneficiation effect, gravity-flotation combination separation method are chosen for patchy mercury method. Using the gravity separation to discard large amount of waste rocks, reducing the grinding and flotation equipment investment cost. Flotation is used to purify the mercury ore after gravity separation.

Hand selection method is based on the difference in color and shape between the mercury ore and waste rock color. It need low production cost, get high concentrate grade, but it can not be used in fine mercury ore beneficiation and need large labor intensity.

The gravity separation applies to the handling of blotchy and coarse disseminated mercury ore with high beneficiation efficiency, small investment, low operating costs, no environmental pollution and disadvantages would be the low recovery for fine disseminated mercury ore.

Flotation method is mainly used to extract mercury disseminated ores since the mercuric sulfide ores has good floatability. It can achieve higher indicators and desired purity and recovery requirements, but it needs large investment, high operating costs, as well as there are certain pollution to environment.

Mercury ore gravity separation process: breaking-screening-Jigging-shaking.

Mercury ore flotation process: breaking-screening-Grinding-Classification-stir-Flotation-filter press.

Mercury ore gravity-flotation process: crushing-screening-gravity separation-dehydration-Grinding-Classification-stir-Flotation-filter press.