Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Limonite Iron Separation

Still looking for iron separator? Forui limonite iron separator includes gravity separator, magnetic separator, dewatering screen, etc. Forui never let you down with its high quality iron separator.

There is something common for beneficiation of iron ore like limonite, hematite and manganese ore. Intensity magnetic separation and gravity separation can be used to upgrade these ores and here is some share about the limonite iron separator and limonite beneficiation flow sheet.

The gravity separator can be a good choice as a limonite iron separator. Gravity separation is used for limonite upgrading of coarse granule inlay and high single separation degree. Limonite ore is easy to get argillization, so milling shall be avoided for coarse limonite inlay and no ball mill when crushing can make limonite granules liberated from impurities. The following is the picture of limonite from Malaysia:

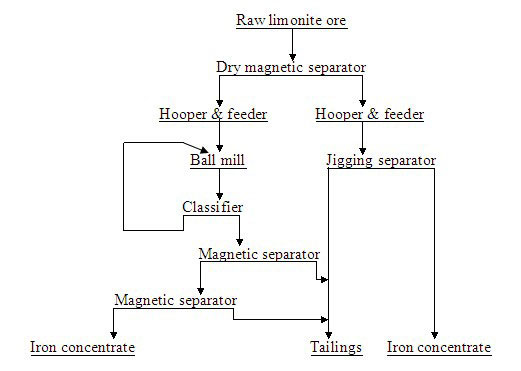

This limonite iron needs no crushing with its high liberation degree, and washing and jigging can help to get high limonite concentrate. The yellow stones are waste stones and the black brown mineral is limonite and magnetite. This iron ore is paragenic ore of limonite and magnetite with the liberation size of 0-5mm. Flow sheet for this iron ore from Forui is magnetic separation, jigging separation and dewatering screen. The details as below:

The limonite ore is dry with low water content and small granules. Dry magnetic separator can help to get the magnetite in the ore. Tailings from magnetic separator will go for iron separator-jig concentrator through hopper and feeder to gain high grade limonite concentrate. The iron concentrate from dry magnetic separator can not meet the need and it shall be milled and classifying and further magnetic separator to get concentrate of +67% Fe. The concentrate from jig concentrator can be 55-66% of Fe and both concentrate can be ok to sell. The client asked a daily capacity of 3000t. after magnetic separator of 1200*3000, about 2000t can be left and then 4 2LTC6109/8T trapezoidal jig concentrator can be ok to meet the capacity. Ball mill of 2400*4500 can liberate the iron granules, and the final wet magnetic separator can be enough to get concentrate of 67% Fe.

The limonite ore is dry with low water content and small granules. Dry magnetic separator can help to get the magnetite in the ore. Tailings from magnetic separator will go for iron separator-jig concentrator through hopper and feeder to gain high grade limonite concentrate. The iron concentrate from dry magnetic separator can not meet the need and it shall be milled and classifying and further magnetic separator to get concentrate of +67% Fe. The concentrate from jig concentrator can be 55-66% of Fe and both concentrate can be ok to sell. The client asked a daily capacity of 3000t. after magnetic separator of 1200*3000, about 2000t can be left and then 4 2LTC6109/8T trapezoidal jig concentrator can be ok to meet the capacity. Ball mill of 2400*4500 can liberate the iron granules, and the final wet magnetic separator can be enough to get concentrate of 67% Fe.

Forui, a professional manufacturer of iron separator which includes jig concentrators, ore log washers, vibration screens, dewatering screen and ball mills. And we can do free test with our iron separator if samples can be available.