Product Navigation

News & Events

- Jig Machine for Gold Separating05-07-2015

- Shaking Table and Jigger for Mercury O…05-05-2015

- Rough Separation and Further Selection…04-29-2015

- Tantalum Ore Beneficiation Process04-23-2015

- Galena Beneficiation Method04-21-2015

Chromite Beneficiation Process

Chromite is a mineral composed primarily of iron, magnesium and chromium oxide: (Fe, Mg) Cr2O4. Chromite can be dressed by gravity separation or magnetic separation.

Chromite Beneficiation Process

Chromite is a mineral composed primarily of iron, magnesium and chromium oxide: (Fe, Mg) Cr2O4. It is a kind of spinel, the only chrome ore can be mined. The mineral composition is complex with uncertain magnesium content, sometimes also mixed with aluminum and iron. Cr2O3 content in Chromite is 67.91%, which is a major source of industrial chromium, can also be used as high-temperature refractory material, such as chrome bricks. Holmes hardness of 5.5 to 6, specific gravity of 3.9 to 4.8, weak magnetic.

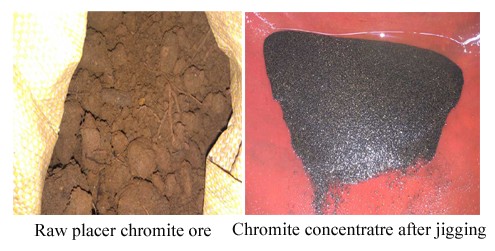

From the physical properties of chromite we know, chromite can be dressed by gravity separation or magnetic separation. In the actual production, float purification can also be used, but the most commonly used method is gravity separation, magnetic separation and flotation application are used very rare. As a professional manufacturer of mineral processing equipment, Forui Machinery introduce to you a common chromite beneficiation process.

1. Jaw crusher for primary crushing;

2. Circular vibrating screen for screening;

3. Ores with particles size more than 30mm enter fine jaw crusher for secondary crushing;

4. With ores size less than 30mm, chromite ore from the fine jaw crusher enter the rod mill silo through vibrating screen for coarse grinding to break the intergrowth body;

5. Use jig machine for gravity separation for the extraction of chromite ore, tailings go into the magnetic separator for sweep selection . Magnetic separation process is designed to recycle intergrowth chromite ore that can not be recycled by jig machine;

6. The Chromite concentrates get by magnetic recovery are further grinded in the grinding mill to improve the degree of dissociation;

7. Monomers enter shaker gravity separation to obtain the final concentrate and tailings.

CLICK FOR MORE OF CHROMITE ORE DRESSING SOLUTIONS

CLICK FOR MORE OF CHROMITE ORE DRESSING SOLUTIONS

Should any products be of interest to you, please feel free to contact us via Email: info@frjigmachine.com or complete the form below, and we will contact you as soon as possible.